The new generation of drum emptying at Merck

In order to further automate the supply of its filling plant in Darmstadt while complying with the highest safety and hygiene requirements, Merck was looking for a modern solution for automated drum loading and unloading. SERVOLIFT implemented a complete drum tipping unit for Merck, including conveyor technology, which was seamlessly integrated into the existing production environment.

Challange

Merck KGaA wanted to modernize its existing filling plant and expand it with a new, high-performance drum feeding and tilting system. The main challenge was:

- Ensure high plant availability – 8,160 hours/year in 24/7 operation

- Reliably and safely process a complex variety of materials (over 400 formulations, some of which are sticky, hygroscopic, organic/inorganic)

- Seamlessly integrate the plant into the existing infrastructure, including: conveyor systems, control system (Siemens S7, HMI), on-site media, and interfaces to existing production systems

- At the same time, meet the highest safety and hygiene requirements of the pharmaceutical industry – including regular manual cleaning and complete disassembly after each product change

Particularly critical: The new drum tipper unit had to support two operating modes:

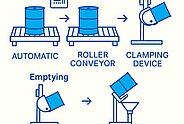

- Automatic barrel feeding and emptying via roller conveyors

- Direct feeding (e.g., bags/cardboard boxes) into the bunker – with complete protection against incorrect operation

Solution

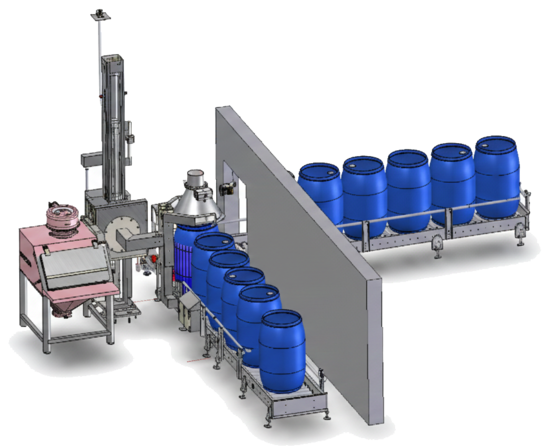

SERVOLIFT developed a fully integrated task solution consisting of:

✔ Intelligent roller conveyor technology

Transport of up to 6 drums (200-liter plastic drums, max. 200 kg)

Positioning via multiple stopper stages and light barriers

Automatically synchronized with the drum tipper

✔ New barrel tipper with pharmaceutical design

Material construction entirely in stainless steel 1.4404 / 1.4435

Surface quality Ra ≤ 0.8 µm for surfaces in contact with the product

Dead space-free, easy-to-clean design

Ergonomic clamping and tilting mechanism up to 180°

✔ Automated process flow

Barrel identification and automatic feeding

Lifting, clamping, tilting, and emptying into the bunker

Automatic return of the empty barrel

Trouble-free operator guidance via Siemens HMI at two locations

✔ Safety and compliance

Full CE conformity, including risk assessment

Safety interlocks, laser scanners, safety doors

Operating mode selection: automatic, manual, service, CIP

✔ Easy cleaning and servicing

Tool-free disassembly of key components

CIP mode for controlled manual cleaning

Recommended maintenance and lubrication concepts in accordance with TGP 0027 (USDA‑H1)

Benefits / advantages for the customer

✔ Significantly increased efficiency in the filling process

The fully automated tilting and conveying process has massively reduced manual effort and stabilized filling cycle times.

✔ Higher process reliability

No access to moving parts, locked operating modes, and safe media shut-off—ideal for pharmaceutical safety standards.

✔ Hygienic design for frequent product changes

Complete daily cleaning is easy. The smooth stainless steel surfaces prevent product adhesion – a must with 400 recipes.

✔ Future-proof integration

The system is fully integrated into the Merck control concept (Siemens S7 / HMI, EMR standards, TGP standards) and can therefore be maintained and expanded over the long term.

Result

The new drum tipper unit increases plant availability, reduces operating errors, optimizes material flow, and at the same time meets all pharmaceutical requirements for safety, hygiene, and documentation.

Thanks to complete integration into the existing production environment, Merck was able to:

- Reduce operator workload

- Standardize processes

- Minimize downtime

- Increase product purity and safety

The solution now represents a modern, fully automated, and validatable task process for drums and alternative containers—ideal for 24/7 operation in active ingredient manufacturing.